Elasticity Property Of Matter

Elastic Limit Formula

From our common experience, we know that when a rubber cord is pulled, it increases in length. But in order to increase the length of a steel wire of same diameter by the same amount, a greater force needs to be applied.

- When equal and opposite external forces act on a body, the different point masses of the body undergo relative displacements. As a result, the body undergoes a change in its shape or size, or both.

- In this condition, a reaction force develops inside the body which opposes the change. If this change lies within a definite limit then the body regains its original state once the forces are withdrawn.

- The property which opposes deformation is present in all materials. This general property of matter is known as elasticity (or the elastic property of matter).

Elastic Definition: The property by virtue of which a body resists the deformation in shape or volume or both due to external forces acting on it and regains its original shape or volume when these external forces are withdrawn is called elasticity. This property is present in every material, irrespective of whether it is solid, liquid, or gas.

Read and Learn More: Class 11 Physics Notes

Elasticity of rubber and Steel: From the viewpoint of physics, a body is said to be more elastic if it has a greater ability to resist deformation against the external force.

- The greater the external force necessary to produce a definite change in the size or shape of a body, the more elastic is the material of the body.

- As mentioned earlier, in order to produce an equal deformation in a steel wire and a rubber wire of the same dimensions, a greater force is necessary in the of the steel wire. For this reason, steel is more elastic than rubber.

Factors Affecting Elasticity:

- The presence of impurities in a metal changes its elastic property.

- If a metal is deformed frequently, then its elasticity decreases. For example, if a thick copper wire is often twisted, it becomes hard and brittle.

- The elasticity of a metal changes with temperature. Usually, its elasticity decreases when temperature increases, and vice versa.

- An exception to this rule occurs in the case of invar —whose elasticity does not change with any change in temperature. Again if a metal is first heated and then cooled, i.e., it is softened, its elasticity gradually decreases

Elasticity Some Useful Definitions

Perfectly elastic body: If after the withdrawal of external forces, a body completely regains its original shape and volume, then it is called a perfectly elastic body.

- In real life, however, a body cannot be perfectly elastic for all magnitudes of external forces. Up to a certain limiting value of external force, a body behaves as a perfectly elastic body.

- This limit is known as the elastic limit for the material of the body. Different materials have different elastic limits. For example, the elastic limit of steel is very high while that of rubber is very low.

Perfectly plastic or inelastic body: if a body, elongated (or compressed) by external forces remains in that deformed state even after the withdrawal of these deforming forces, it is called a perfectly plastic or inelastic body. Actually, no material is perfectly inelastic, though clay comes very close to it.

Partly elastic body: If after the withdrawal of external forces, a deformed body only partially regains its original shape and volume then it is called a partly elastic body. Practically all materials are partly elastic.

Strain: Under the influence of external forces, when a body gets deformed, the different parts of the body suffer relative displacements. As a result, the body undergoes a change in length, volume, or shape.

Strain of a body is defined as the change of its length, volume, or shape relative to its original length, volume, or shape before deformation. So, it is a ratio of two identical quantities and hence it has no unit, i.e., strain is a dimen¬sionless quantity.

Stress: When a body gets deformed under the influence of external forces, a reaction force develops in the body because of elasticity.

This force tries to resist the external forces and helps to bring the body back to its unstrained condition after the deforming forces are withdrawn. The reaction force acting per unit area of the cross-section of the body is called stress.

Since action and reaction are opposite but equal, stress is equal in magnitude to the force applied per unit area of the deformed body.

Stress = \(\frac{\text { applied force }}{\text { area of cross-section of the body }}\)

Units and dimension of stress:

- dyn. cm-2 CGS system

- N. m-2 SI

Dimensional of stress = \(\frac{\text { dimension of force }}{\text { dimension of area }}=\frac{M L T^{-2}}{L^2}\) = ML-1T-2

We shall see that the units and dimension of stress is the same as that of pressure.

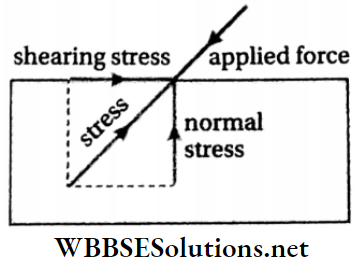

Normal stress and shearing or tangential stress: An applied force can act normally or obliquely on the surface of a body. The component of the reaction force perpendicular to a unit area of the surface is called normal stress.

- When there is any change in the length of a wire or in the volume of a body, normal stress is developed. The stress associated with an increase in length is called tensile stress and that associated with a decrease is called compressive stress.

- On the other hand, the component of the reaction force parallel to a unit area of the surface is called shearing stress or tangential stress. Usually, shearing stress is developed during any change in the shape of a body.

Breaking load and breaking stress: if the external force exceeds the elastic limit, then a strained body cannot return to its original size or shape even after the deforming force is withdrawn.

- In such a case, the body gets perma¬nently deformed. If the amount of the external force is increased gradually, then, for a particular value of the applied force, the body breaks or snaps.

- The magnitude of force, or load, for which the body breaks or snaps is called the breaking load of that body. In that condition, the maximum reaction force developed per unit area of the surface of the body is called breaking stress. Every material has its characteristic breaking stress.

Elasticity Hooke’s Law

The fundamental law of elasticity was propounded by Robert Hooke in 1676. Later Thomas Young expressed this lawin the following way.

Hooke’s Law Experiment Procedure

Statement: Within the elastic limit of a substance, stress is directly proportional to strain.

Hence, stress ∝ strain or, \(\frac{\text { stress }}{\text { strain }}\) = constant

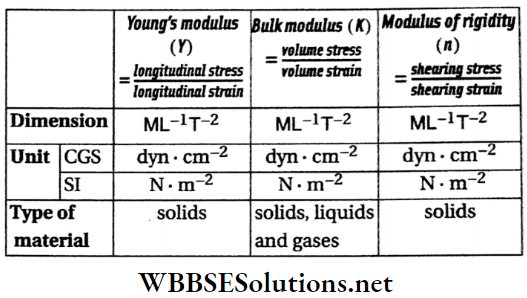

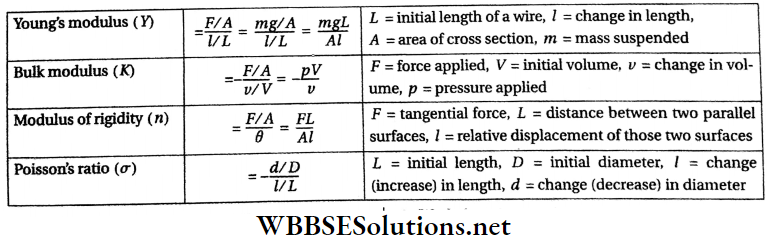

This constant is called the modulus of elasticity for the material of the body. Therefore, the stress developed for unit strain is defined as the modulus of elasticity.

This modulus depends on the material of the body. The modulus of elasticity changes with temperature, in general. Usually, its value decreases with an increase in temperature.

Units and dimension of the modulus of elasticity: Since strain has no unit, the modulus of elasticity has the unit of stress.

Relation: \(1 \mathrm{~N} \cdot \mathrm{m}^{-2}(1 \mathrm{~Pa})=\frac{1 \mathrm{~N}}{1 \mathrm{~m}^2}=\frac{10^5 \mathrm{dyn}}{10^4 \mathrm{~cm}^2}\)

= \(10 \mathrm{dyn} \cdot \mathrm{cm}^{-2}\)

Similarly, the dimensions of the modulus of elasticity and of

stress are identical, which is ML-1T-2.

ElasticityStress Strain Graph (Load Exten Sion Graph Of A String)

Applications of Hooke’s Law in Experiments

Suppose a wire of uniform cross-section is clamped at its upper end with rigid support and a load is applied at its lower end which is then gradually increased.

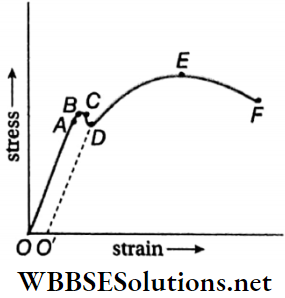

As a result, the length of the wire goes on increasing. In the stress- strain graph of a ductile metallic wire has been shown. The different parts of this graph are described below.

1. Straight line OA: In this section, the stress on the wire is proportional to the strain, which means that the metal follows Hooke’s Aaftr. The wire behaves like a completely elastic body up to the point A.

2. Point A: This point indicates the proportionality limit.

3. Line segment AB: In this section, the ratio of stress and strain is comparatively less, which means that the metal does not follow Hooke’s law. However, after reaching this section of strain, if the stress is removed, then the wire will regain its original length, which means that the strain will again be zero.

4. Point B: This point indicates the elastic limit. In the case of most metals, the two points A and 6 are found to be quite close to each other. In the case of glass, A, and B are identical points and in the case of rubber, the distance between A and B is quite high.

5. Line segment BC: In this section, stress divided by strain becomes even less and the metal gradually loses its elastic property and becomes plastic. After reaching this section of strain, if the stress is removed, then the wire is unable to regain its original length. So, the wire undergoes a permanent deformation.

6. Point C: This point is called the yield point or the upper yield point. At this point, the stress level is known as yield stress. The yield point for most substances can¬not be determined accurately.

Limitations of Hooke’s Law in Experiments

7. Line segment CD: In this section, stress divided by strain is negative. It implies that even if stress is decreased, strain will increase.

8. Point D: This point is called the lower yield point. If the stress is gradually decreased after the strain reaches this point, the return graph is not along DO, but along DO’. In this case OO’ indicates the permanent deformation.

For bodies with nearly perfect elasticity, the points A, B, C, and D are situated so close to one another that practically the four points can be assumed to be identical.

9. Line segment DE: In this section, stress divided by strain is the least and the metal becomes plastic. The cross-section of certain parts of a wire becomes comparatively lower than that of the remaining parts.

10. Point E: At point E the stress reaches its maximum value. At this point, the material of the wire flows like a viscous liquid and the wire becomes thin. Now, even if the load is decreased, the wire goes on thinning down.

11. Line segment EF: In this section, the area of the cross-section at different parts of the wire starts decreasing fast.

12. point F: At this point, the wire snaps from its weakest part. The stress corresponding to the point F is called breaking stress or the ultimate stress. This point F is called fracture or breaking point.

Ductile material: The materials which have large plastic range of extension are called ductile materials. As shown in the stress-strain curve in Fig, their fracture or breaking point is widely separated from the elastic limit. Such materials undergo an irreversible increase in length before snapping. So they can be drawn into thin wires. Copper, silver, iron, aluminum, etc., are examples of ductile materials.

Brittle material: The materials which have very small range of plastic limit of extension are called brittle materials.

Such materials break as soon as the stress is increased beyond the elastic limit. Their breaking point lies just close to their elastic limit as shown. Cast iron, glass, ceramic, etc., are examples of brittle materials.

Necessity of the stress-strain graph: For practical purposes, knowledge of the load-extension graph of a metal is absolutely essential. From this graph, the elastic limit of the material can be known.

For example, during the use of a machine, the stress developed on the axle or the other parts of the machine should be kept below the elastic limit of its material. For this, the stress-strain or the load-extension graphs of different materials are highly useful.

Elastic fatigue: If the force (or load) applied on an elastic body rises and falls rapidly and this periodic fluctuation continues for a long time, then the elastic property of the body gets degraded, even if the elastic limit for the material is not exceeded.

- It means that the body remains permanently deformed in some respect, i.e.„ some part of the body becomes thinner and weaker, even after the deforming force is withdrawn. The body may then break or snap at a load less than the normal breaking load.

- This kind of degradation of the elastic property of material due to rapid changes in stress is called elastic fatigue.

Elasticity Experimental Verification Of Hooke’s Law Determination Of Young’s Modulus

Calculating Spring Constant from Hooke’s Law

Searle’s Experiment: A uniform metal wire, about 2 to 3 m long, is hung from the roof of the laboratory. Initially, a small weight, usually called zero-load, is attached to the lower end of the wire. With the help of a screw gauge, the average diameter of the experimental wire is measured. Its length (L) is determined using a metre scale.

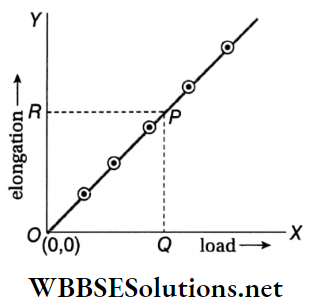

The load at the lower end of the wire is then gradually increased. Measuring the corresponding extensions with suitably fitted verniers, a graph can be plotted with the load along the X-axis and the elongation along the Y-axis. The graph passes through the origin and is a straight line.

Experimental Verification of Hooke’s Law

As the graph is a straight line, we can say that, load ∝ elongation, i.e., stress ∝ strain (within the elastic limit). This proves the validity of Hooke’s law.

Calculation: From any point P on the graph, two perpendiculars are drawn on the axes.

Here, OQ = load (mg); OR = elongation (l).

Therefore, the longitudinal stress \(\frac{m g}{\pi r^2}\) and the longitudinal.

∴ Y = \(\frac{\text { longitudinal stress }}{\text { longitudinal strain }}=\frac{\frac{m g}{\pi r^2}}{\frac{l}{L}}=\frac{m g L}{\pi r^2 l}\)

Since the quantities on the right-hand side of the above expression are known, the value of Young’s modulus (Y) can be determined.

| Class 11 Physics | Class 12 Maths | Class 11 Chemistry |

| NEET Foundation | Class 12 Physics | NEET Physics |

Elasticity Synopsis

The property by virtue of which a body resists the defor¬mation either in shape or in volume or both, due to application of external forces on it and recovers its original shape or volume when the deforming force is withdrawn, is called elasticity.

- A body cannot be perfectly elastic for all magnitudes of external force. Only up to a certain limit of external force a body can be perfectly elastic. This limit is known as the elastic limit for the material of that body.

- Actually there is no perfectly elastic or perfectly inelastic material, rather all materials can be treated as partially elastic.

Under the influence of external deforming force the reaction force developed per unit area of cross section of a body is called stress. Stress of a body can be expressed as

stress = \(\frac{\text { applied force }}{\text { area of cross-section of the body }}\)

- Relative displacements of different parts of an elastic body occur under the influence of external deforming force. As a result, the body undergoes change in length, volume, or shape. The fractional change in these quanti¬ties is known as strain.

- Strain is always represented by the ratio of two identical quantities. It has no unit its dimension = 1

- The applied force or load for which a body snaps or breaks is called the breaking load.

Hooke’s law: Within elastic limit, stress is directly proportional to strain. The amount of stress developed per unit strain is called elastic modulus.

Dimensions of elastic modulus and stress are identical and is ML-1T-2.

- The amount of force applied to produce unit elongation in a spring is called its force constant. Force constant of a spring represents its stiffness.

- The loss in elastic capability of a body due to repeated and rapid increase or decrease in the force applied on it is known as elastic fatigue.

Elasticity Useful Relations For Solving Numerical Problems

Hooke’s law: \(\frac{\text { stress }}{\text { strain }}=\text { elastic modulus }\)

Y = \(3 K(1-2 \sigma)=2 n(1+\sigma), \sigma=\frac{3 K-2 n}{6 K+2 n}\)

⇒ \(\frac{9}{Y}=\frac{1}{K}+\frac{3}{n}\)

Work done in stretching wire,

Hooke’s Law

W = \(\frac{1}{2} F l=\frac{1}{2} \frac{Y A l^2}{L}\)

In deforming a body, the work done per unit volume potential energy stored per unit volume of the body (energy density) = 1/2 x stress x strain .

For a force F applied on a spring, if its increase in length is x, then F∝x or, F = kx (where k = force constant of the spring]